Laser Welding Machine Provides High-Quality Welds for Metal Products

The Importance of a Laser Welding Machine for Welding Metallworking

Obtaining most excellent results for metal product welds is a high priority. Laser Welding Machine addresses this concern. The industry has benefited from this technology due to its excellent results compared to traditional methods. The weld quality for metal products, especially in construction and automotive fields, influences the product lifetime and the overall performance. Safety issues, increased costs for frequent breakdowns, and repairs or replacements are the results of a poor weld. Having the right Laser Welding Machine fixes most of these problems.

It’s not just laser welding speed that is impressive; it’s also the attention to detail with every weld and the consistency and strength it offers with every weld. Traditional welding tools can introduce uneven seams and excessive heat damage to the surrounding areas. Laser welding uses a concentrated beam that evenly focuses on the exact weld area. The rest of the part is untouched. The welded part retains strength and shape. This is great for manufacturers looking to provide high-quality products for consumers.

How the Laser Welders Work for Quality Welds

The design and laser welding machine's working principle are the reasons for its high-quality welds. First off, the laser beam is concentrated and focused to a small point. This small point creates a high power density at the focal area. When the laser beam focuses on the metal, the heat input from the beam exceeds what the metal can reflect, conduct, and distribute. The metal in that area reaches the vaporization temperature quickly, forming a small hole. As the laser beam moves over the area to be welded, the hole keeps forming a narrow slit in the weld.The process is so precise that it produces narrow weld seams. This means less deformation of the metal product. Since the heat is concentrated only on the weld, the part of the metal near the weld (the heat-affected zone) is very small. This is good because a weak heat-affected zone is prone to cracking. Also, there is no mechanical pressure on the product because the laser beam doesn’t directly touch the metal and it will not undergo deformation from the tools pressing on the metal during welding.

Benefits of the Machine Structure to the Quality of Welds

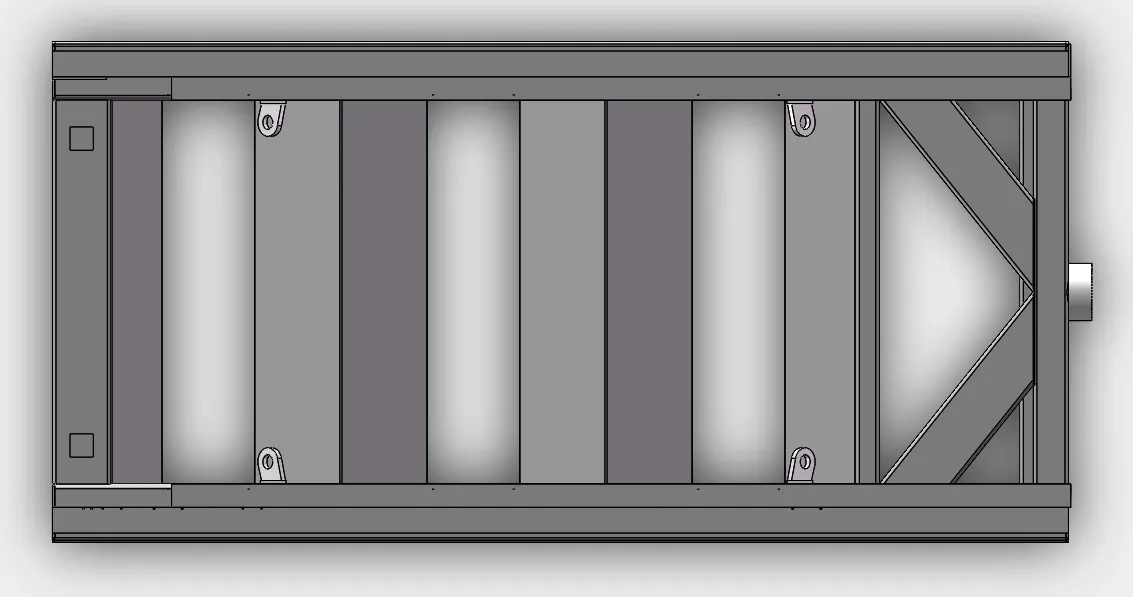

The design of the Laser Welding Machine plays an important part in the quality of the welds produced. First the machine tool is welded completely, then it is annealed to relieve internal stress. After this, it proceeds to roughing, finishing, and vibration aging. All of these steps are aimed to relieve the stress from processing and welding. Why is this important? Internal stress in the machine tool will compromise the machine’s accuracy after time. If a machine possesses good stability, it will retain its accuracy for a long time and will produce consistent welds.

The design details on this machine tool are also impressive. For instance, the guide plate contains a 30 mm base plate and welding included. Within the machine bed, two air ducts create a Y-shaped design. Each duct is 250 mm in diameter, allowing for thorough, low-resistance air flow. This is crucial during welding, since hazardous smoke and dust are produced. Effective smoke extraction helps maintain a clean workspace, prevents debris interference during welding, and enables air extraction to avoid disrupting the work being performed.

This machine tool features double racks, double guides, and a four-sliding-block drive structure. The guide rail is precision class H heavy load type and with H class precision. The protective cover is fully enclosed and resistant to fire and oil. The rack is from Taiwan's JT brand, SHGH series, with M2 oblique teeth and 6-level precision. All these components work together to contribute to the smooth and accurate movement of the machine. The movement also allows the laser beam to follow the welding path with precision so the welds are seamless.

How the Machine Design Improves User Experience and Weld Constancy

The machine performs well because of its design; however, it also takes into account user experience, which contributes to the consistency of the welds. The bottom of the machine bed, for example, is a side pumping hopper, which facilitates the easy discharge of materials. Its narrower width is more effective for dust removal. The ground foot is a newly designed adjustment support. This support, after testing, can improve the overall stability of the machine. This is important because a machine that is stable won’t shake, which is needed to keep the laser beam steady.

Adjacent to the machine, the enclosed spaces created assist with air circulation. Additionally, there is a gradient sealing plate for air extraction. This plate ensures the air exhaust is a two-dimensional air extraction reducing the use of segmented air extraction. The new guide rack is shaped to decreased processing time thereby cutting costs. It also accommodates an oil return mechanism. This allows the guide rail to be lubricated automatically and eliminates the need for a user to oil the guide rail with a manual yellow oil pump. The guide rail will no longer be neglected to cause an excessive wear. Machines work best when all the components are in good working condition and don’t wear out. This ensures that every weld is as good as the first one.

These design elements result in a machine that is dependable, simple to use, and produces excellent quality welds on metal items. Every aspect is done with the needs of manufacturers that produce quality metal items in mind, from the precision of the laser beam and the stability of the machine tool to the simplicity of the operable elements.