What are the noise levels of modern laser systems?

One thing that you may not have thought about laser machines, but is very important for your shop, is the noise of the machines. The noise, especially in industrial environments, is not merely annoying, it affects the comfort of the operator, their safety, the ability for everyone to communicate, and overall, the noise affects productivity in the shop. As such, it is very reasonable to ask the question on the laser cutting machine or laser welding machine you're getting: how loud will it be?

Fortunately, the noise levels of laser machines have been significantly reduced and modern laser systems are substantially quieter than their older versions.

The Silent Progress of Modern Laser Systems

For most people, the main noise cause will not be the laser beam itself, which is silent. The noise originates from the complementary systems that make the laser systems function. Here is a breakdown of the major noise sources.

Identifying The Main Noise Factors In Your Laser System

Noise from any source can be an irritant, but knowing the cause makes it easier to manage. In most modern fiber laser setups, the primary noise sources are the chiller unit, the exhaust system, and the motion control elements such as drives and motors.

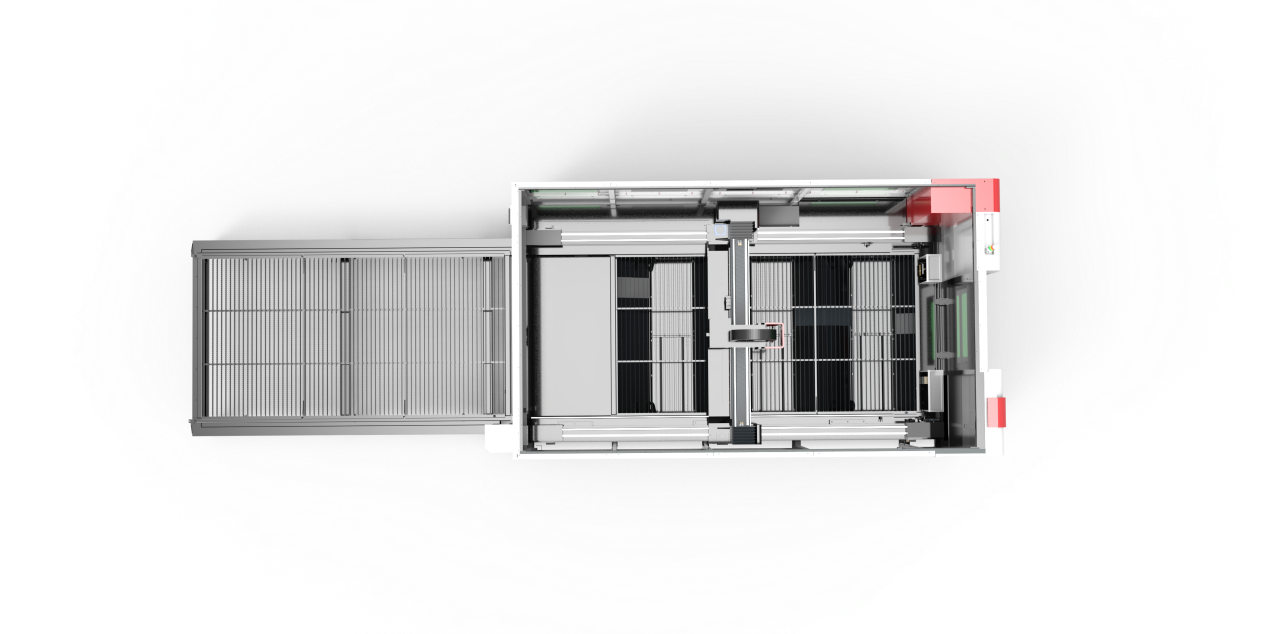

The chiller keeps the laser source and optics at operating temperature. It contains components like compressors and pumps, which create a consistent, low-frequency hum. The exhaust fan also makes significant noise, especially when it ramps up to clear smoke from cutting or welding thick materials. The movement of the gantry, the servo motors, and the cutting head can create mechanical and drive noises, but these are typically less dominant than the exhaust or chiller.

Factors such as machine configuration, its power, and the specific processing task greatly affect the overall noise level. A high-power laser cutting machine processing thick steel will be noisier compared to a precision laser welding machine working on thin sheet metal.

How Quiet Are Modern Laser Cutting Machines?

Just a few years ago, a busy laser cutting cell often had an average noise level of 85 decibels (dB) or more, necessitating hearing protection for anyone working a full shift nearby.

Modern design has proactively cut this noise. Contemporary fiber laser cutting machines built to high standards typically operate in the range of 70-78 dB during standard cutting. To put this in perspective, 70 dB is similar to the noise of a busy vacuum cleaner, and 78 dB is comparable to the sound inside a passing car.

This achievement stems from several modifications. Enclosures now feature better sound-dampening materials. Vibration isolation pads are standard to prevent motor hum from transmitting through the floor. Perhaps the most significant improvement is the integration of variable-frequency drives (VFDs) on exhaust fans. This allows the system to run the fan only as fast as necessary for the immediate task, drastically reducing excess noise. In many modern systems, the fan gently ramps up at the start of a cut and then settles into a lower, quieter operational hum.

The Gentle Humming of Laser Welding Machines

Laser welding machines generally present a different—and often lower—noise profile than cutting systems. The process generates fewer fumes, meaning the exhaust system doesn't have to work as hard or as loudly. The most prominent noise sources in a welding system are typically the chiller and the internal cooling fans for the laser source.

For standalone robotic laser welding cells, the most common audible sound is the smooth motion of the robotic arm, which is usually a low, rhythmic hum. Handheld laser welding systems can be exceptionally quiet in operation, as the core components (laser source, chiller) are housed in a separate cabinet that can be placed away from the immediate workspace. The operator at the welding point primarily hears the subtle sound of the arc and a faint system hum. For many workshops, integrating this technology means a significant capability upgrade with minimal added noise pollution, a key benefit for mixed-operation facilities.

Engineering a Quieter Future: The Technology Behind the Silence

How do manufacturers actually deliver on the promise of lower decibel levels? It's through a combination of hardware innovation and intelligent system design. Leading manufacturers engineer the complete system for optimal performance, which includes acoustic performance.

Fume extraction now utilizes high-efficiency, low-noise centrifugal fans, which move air effectively without the high-pitched whine of older models. Enclosures have evolved from simple metal boxes to structures lined with sound-absorbing materials that trap sound waves. The strategic placement of noisy components like the chiller compressor, coupled with the use of flexible, insulated ducting, prevents vibrations from being amplified by the machine frame.

Furthermore, the trend toward more compact, integrated designs is beneficial. When the laser source, chiller, and control system are designed as a cohesive unit, it creates more opportunities to manage airflow, vibration, and sound containment from the initial design phase.

Partnering For a Quieter Workshop

When evaluating new laser equipment, specifications for speed, accuracy, and power are paramount. However, the operational environment is equally critical for long-term employee well-being and efficiency. A quieter machine contributes to a more productive and pleasant workspace.

This is where the manufacturer's philosophy becomes key. A company that focuses on providing 'full-scenario intelligent solutions' understands that a machine operates in your workshop, alongside your people. This mindset drives attention to details like noise reduction, ergonomics, and the overall user experience.

Companies that invest heavily in R&D and control their manufacturing vertically—producing supporting equipment in-house—are able to implement quiet technologies holistically at the source. They are not just assemblers; they are engineers of integrated systems. A manufacturer serving a global customer base receives direct feedback on what matters on the shop floor, and operator comfort is consistently high on that list.

Final Thoughts

Today, the noise level of a new laser system is a fundamental design criterion, not an afterthought. You can reasonably expect a state-of-the-art laser cutting machine or laser welding machine to contribute a manageable hum to your workshop, not a disruptive roar. This progress is powered by better components, smarter software controls, and a manufacturer's commitment to creating not only powerful tools but also better working environments.

As you consider your next equipment purchase, listen closely—not just to the sales talk, but to the machines themselves. The quieter option often reflects more thoughtful engineering, promising not only superior performance but also a safer, more comfortable, and more productive space for your most valuable asset: your team.