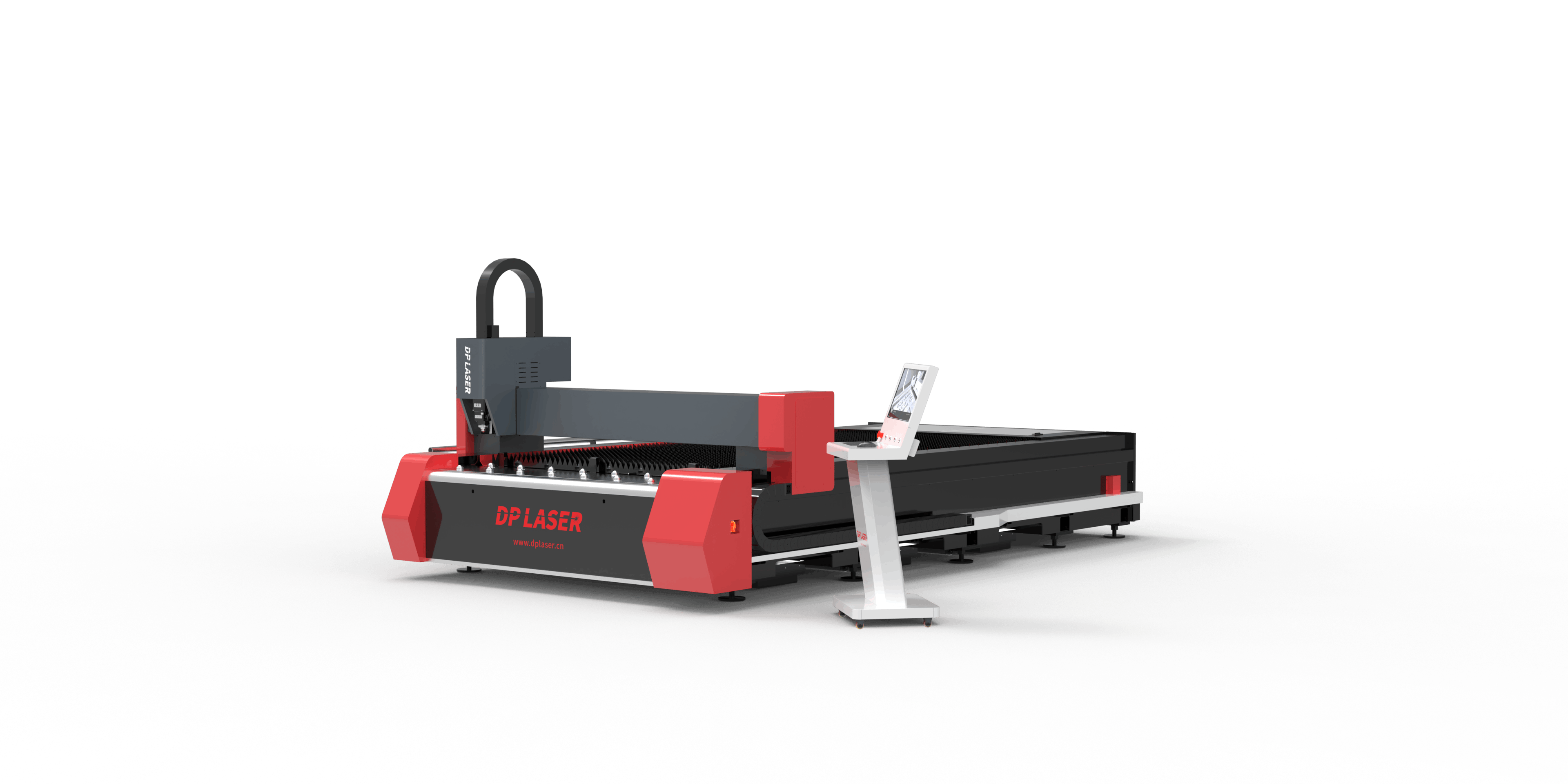

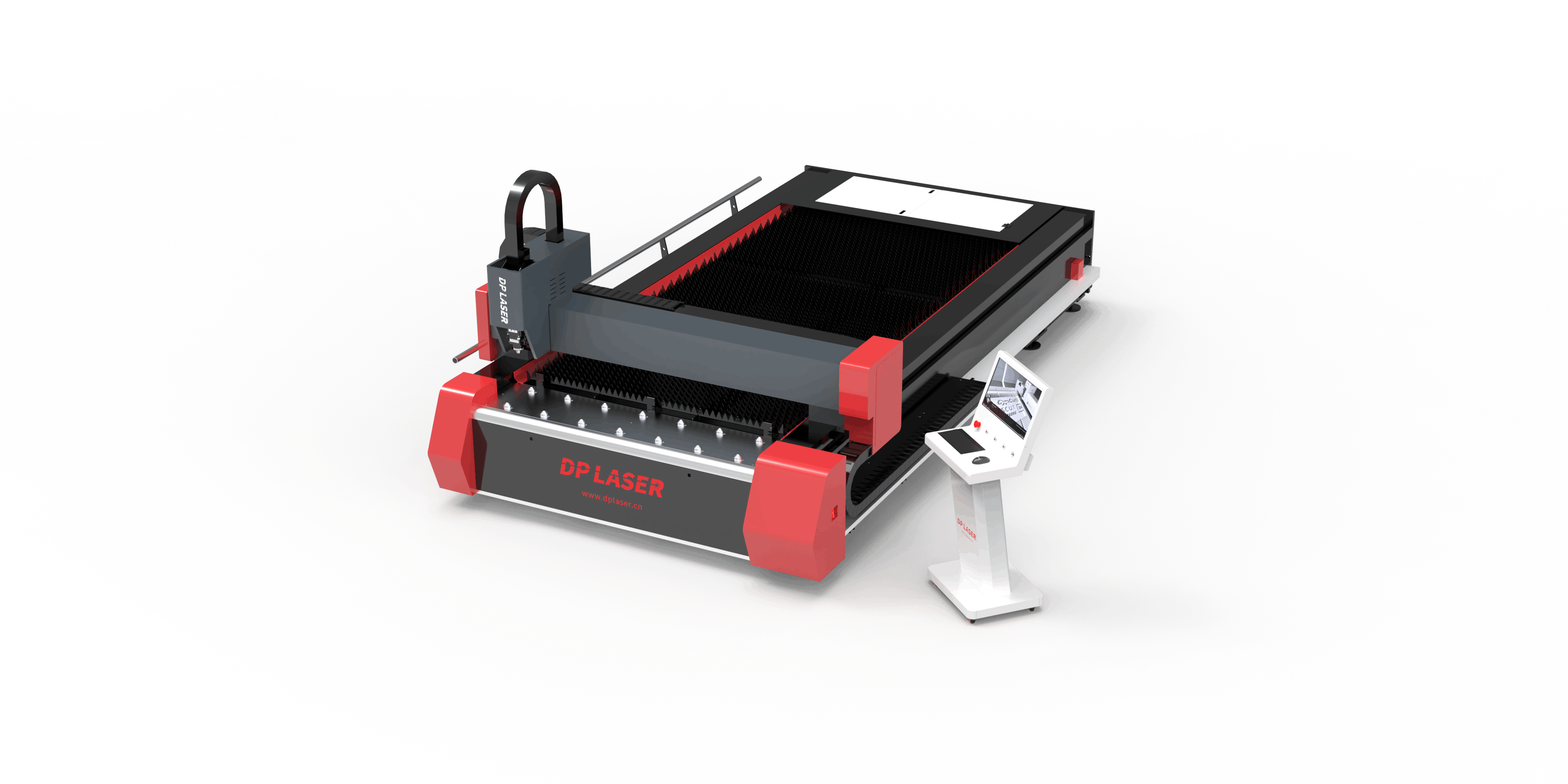

DP LASER CS Series High-Speed Fiber Laser Cutting Machine: Redefining Thin-Sheet Metal Cutting Efficiency

Introduction: Solving the Core "Speed vs. Precision" Pain Point in Thin-Sheet Fabrication

In sheet metal processing-dominated industries such as electrical switch manufacturing, elevator production, home appliances, kitchenware processing, and tool manufacturing, businesses often face a dilemma: they want to boost productivity through high-speed cutting but fear vibration-induced precision degradation and higher scrap rates; they aim to reduce operational costs but must contend with pressures from environmental compliance (e.g., smoke emission regulations in overseas markets) and logistics costs. To address this industry pain point, DP LASER has launched the CS Series High-Speed Fiber Laser Cutting Machine—a solution built on the core philosophy of "high speed without compromising precision"—delivering an integrated solution for efficiency, precision, environmental friendliness, and cost-effectiveness to metal fabricators worldwide.

Core Advantages: Resolving the "Speed vs. Precision" Trade-Off with Technology

The CS Series' competitive edge stems from its seamless integration of fiber laser technology and heavy-duty mechanical structure, fundamentally addressing the traditional laser cutting issue of "faster cutting leads to lower precision."

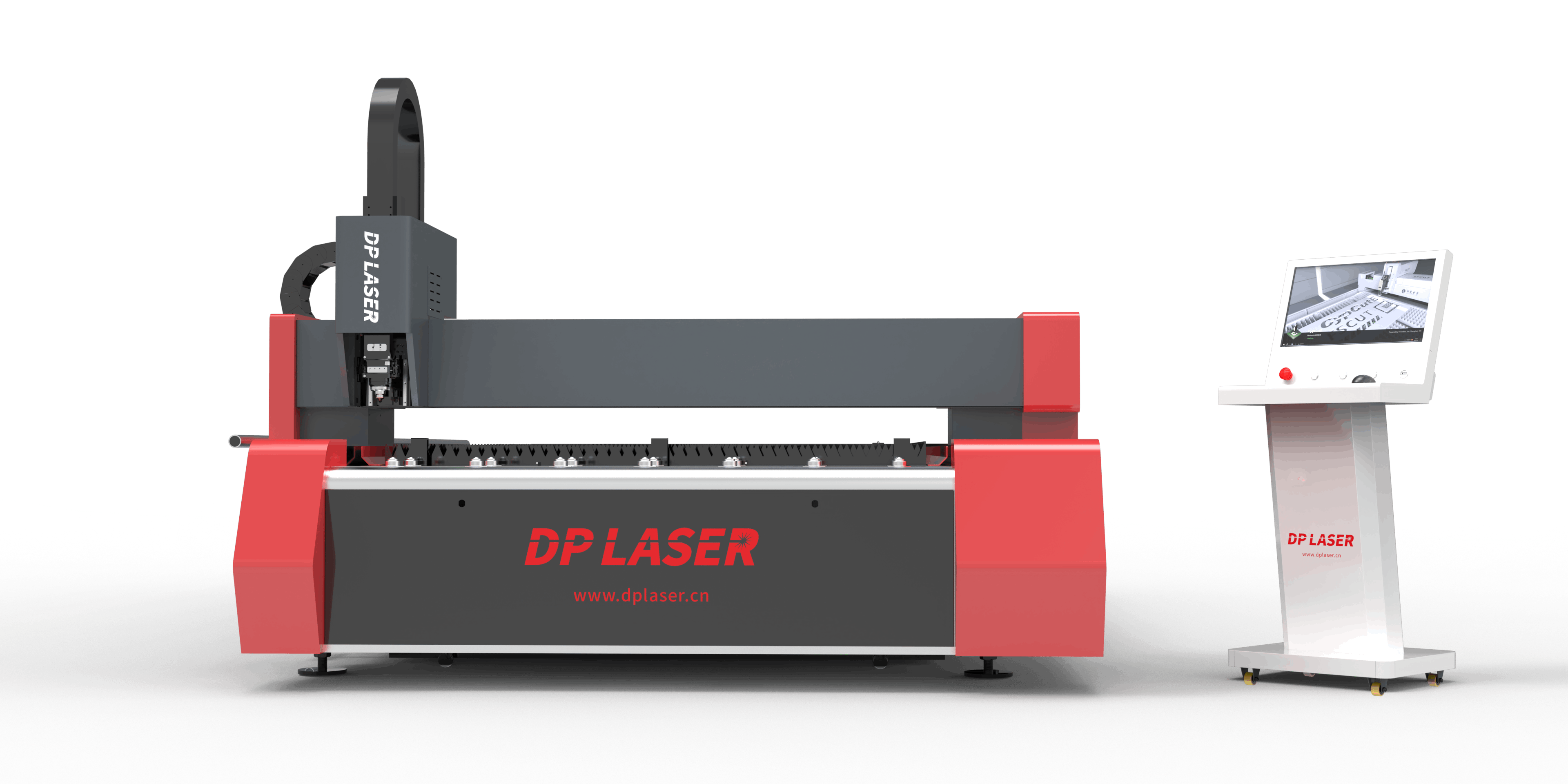

1.High-Speed Stability: ±0.02mm Cutting Tolerance at 2.0G Acceleration

Equipped with a high-performance servo system (response time < 0.1ms) and a heavy-duty machine bed (welded from 40mm thick high-quality steel, stress-relieved via aging treatment), the CS Series incorporates an 8Hz low-pass filter for real-time vibration suppression during high-speed motion. Even at 2.0G peak acceleration (top-tier in the industry), it maintains a ±0.02mm cutting tolerance (equivalent to 1/3 the diameter of a human hair). This "high speed + stability" combination fully addresses the "small parts with high precision" cutting requirements of industries like electrical switches and kitchenware.

2. Lightning-Fast Speed: 30% Faster Than Traditional Lasers, Effectively Boosting Productivity

Through optimized motion control algorithms and 8Hz low-pass filtering technology, the CS Series reduces air-cut time by 40% (lowering the proportion of non-cutting time from 30% (traditional) to 18%), allowing the machine to spend more time on productive cutting.

Actual Data: In 1.5G acceleration and 8Hz low-pass filtering mode, cutting speed for 1.5mm or thinner sheets is 30% faster than traditional models (from 8m/min to 10.4m/min); for 2-3mm sheets, speed increases by 10-25% (from 5m/min to 5.5-6.25m/min).

Impact: Based on 8 hours of daily operation, a single CS Series machine can cut an additional 300 tons of material annually, directly increasing productivity by 20%.

3. Environmental Friendliness & Durability: Meeting Strict Overseas Standards, Reducing Long-Term Costs

High-Efficiency Smoke Extraction & Dust Removal System: Features a dual-fan + multi-stage filtration system with 95% smoke purification efficiency, compliant with the EU Emissions Trading System (ETS) and other strict overseas environmental standards—addressing the concerns of overseas clients.

Climate-Controlled Enclosure: Designed for 24/7 constant temperature (20-25℃) and humidity (<60%RH), it prevents humidity-induced corrosion in the humid environments of Southeast Asia and thermal drift caused by large temperature differences in Europe. This extends the lifespan of the laser source and electronic components by 30%, reducing annual maintenance costs by approximately ¥10,000-20,000.

4. Trade-Friendly: 35% Lower Bulk Procurement Costs, Fast Ramp-Up

Minimalist Loading/Unloading Design: Supports three-side loading (left/right/front), enabling installation and commissioning within 24 hours of delivery (compared to 3-5 days for traditional models) for immediate production.

Logistics Optimization: A single 40HQ container can hold 4-6 C3015 units (3000×1500mm worktable), designed specifically for overseas bulk procurement to reduce logistics costs by over 35%.

Industry Applications: Precisely Matching Thin-Sheet Metal Fabrication Needs

Optimized for 1-3mm thin-sheet metal cutting, the CS Series is widely applicable to:

Electrical Switch Manufacturing: ±0.02mm high precision meets the cutting requirements for complex parts such as small circuit breakers and relays, with high speed boosting productivity.

Elevator Manufacturing: The heavy-duty machine bed and stable performance ensure consistent cutting of large-sized elevator door panels and car components.

Home Appliances/Kitchenware Manufacturing: Fast cutting of complex shapes (e.g., refrigerator panels, range hoods, kitchenware accessories) shortens time-to-market for new products.

ROI: Investment Recoupment in 6-12 Months, Clear Benefits

The CS Series' cost-effectiveness lies not only in its initial procurement cost but also in reduced long-term operating costs:

Productivity Gain: 20% more material cut per day translates to an annual revenue increase of approximately ¥150,000-200,000.

Reduced Maintenance: Climate control and stable design extend equipment lifespan, saving approximately ¥10,000-20,000 in annual maintenance costs.

Lower Scrap Rates: High precision and consistency reduce scrap rates by 5%, cutting annual material waste by approximately ¥15,000-20,000.

Comprehensive Calculation: Customers can typically recoup their equipment investment within 6-12 months, with additional annual profits of ¥100,000-150,000 thereafter.

Choose DP LASER CS Series to Embark on a New Era of Efficient Production

DP LASER's CS Series High-Speed Fiber Laser Cutting Machine, guided by the philosophy of "technology empowers efficiency," provides overseas clients with a metal cutting solution encompassing high speed, precision, environmental friendliness, and low cost. Whether it's the logistics advantages of bulk procurement or the stable performance adapting to different environments, the CS Series is the ideal choice for metal fabricators to enhance their competitiveness.

Contact DP LASER today to get a customized solution and let the CS Series become the efficiency engine of your production line!