Top 3 Trends in the Metal Fabrication Industry in 2026: Is Your Laser Equipment Ready?

Autonomous Production: Transforming Equipment into a Guarantee of Stable Output and Consistent Quality

Client expectations for delivery timelines and quality uniformity have never been higher. Any unplanned downtime or quality fluctuation directly impacts your bottom line.

Frequent job switching between sheet metal and tube processing on conventional equipment often relies on manual trial-and-error for parameter setting, leading to inefficiency and inconsistent results.

The core of next-generation laser cutting and welding equipment lies in "perception" and "decision-making." By integrating vision systems and process databases, equipment can automatically identify material type and thickness before cutting, selecting optimal parameters. During welding, real-time monitoring of the melt pool allows for dynamic adjustment of energy output. This means that whether operating a tube laser cutting machine or a handheld laser welder, the dependency on operator skill is significantly reduced, ensuring stable, reliable output and strengthening your ability to meet client commitments.

Investing in intelligent equipment means investing in "production certainty" and "quality consistency," which is the core capital for securing high-demand, long-term contracts.

Green Manufacturing: Turning Environmental Pressure into Cost Advantage and Market Access

Tightening environmental regulations and client scrutiny over supply chain carbon footprints coincide with the pressing need to optimize operational costs.

High energy consumption from laser cutting equipment and inadequate fume extraction not only affect the workshop environment but can also hinder entry into premium supply chains.

Green manufacturing spans the entire equipment lifecycle. Fiber laser sources with high electro-optical conversion efficiency directly reduce the operating costs of both cutting and welding machines. Integrated, high-performance filtration systems capture fumes at the source. Furthermore, intelligent nesting software dramatically improves material utilization for both sheets and tubes, minimizing waste from the start. Choosing a laser equipment supplier committed to green standards helps lower daily operational costs and positions your shop as a responsible partner in the eyes of discerning clients.

Energy-efficient and environmentally conscious laser equipment is not just a cost-saving tool; it's a green passport to higher-value markets.

Functional Integration and Flexibility: Multi-Task Machines for Diverse Project Wins

The lines between processing services are blurring. Clients increasingly seek a single partner for cutting, welding, and even cleaning needs.

Processing parts that require cutting, welding, and surface cleaning traditionally involves moving workpieces between different stations, harming efficiency and compromising alignment accuracy.

Equipment modularity and versatility are key. Advanced laser processing platforms can switch between cutting heads, welding heads, and cleaning heads, allowing multiple processes on a single machine. Meanwhile, portable laser welders and cleaners offer unparalleled on-site flexibility. This flexible capability enables metal processors to respond swiftly to diverse project requirements, evolving from a single-service job shop into a comprehensive solutions provider.

Building a flexible production core around multi-function laser equipment significantly broadens your service offerings, enhancing client retention and the value derived from each customer relationship.

Conclusion: Partner with Progress to Define Your Own Future

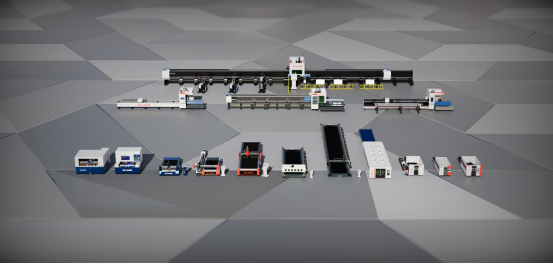

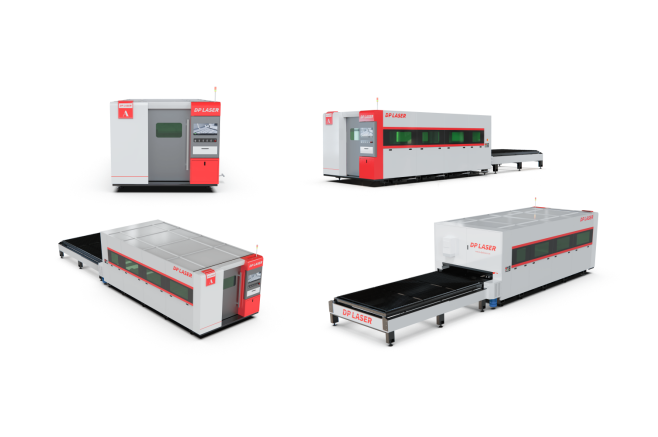

The trends of 2026 represent a market-driven selection process for depth and breadth of processing capability. Your laser cutting machines and welding equipment are no longer just standalone tools; they are the productivity core that defines your business's ceiling. DP Laser focuses on embedding intelligence, sustainability, and flexibility into every fiber laser cutting machine, welding system, and cleaning device, aiming to be the reliable partner for processors facing tomorrow's challenges. The future is now. Upgrading your core equipment is how you lay the foundation for success in the coming decade.