Demystifying Maintenance Costs: How Daily Upkeep Can Double the Lifespan of Your Laser Cutter

Time : 2025-12-31

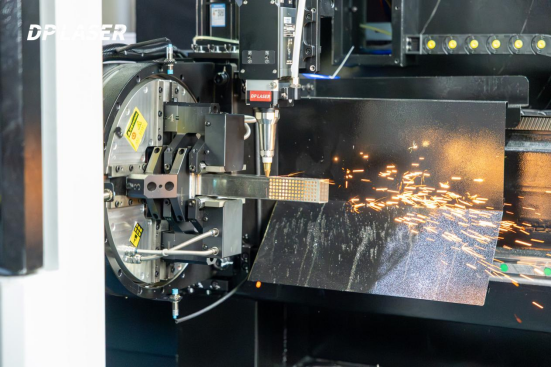

Let's talk about an open secret in the workshop, one that's often tucked away until a machine screeches to a halt: maintenance. For many, the upkeep of a fiber laser cutting machine is viewed purely as an expense—a line item to minimize. But what if we reframed it? Consistent, daily care isn't a cost; it's the highest-return investment you can make in your metal processing capability. It's the decisive factor between facing a sudden, five-figure repair bill and enjoying a machine that delivers peak performance for years beyond its expected life.

Guarding the Optical Heart: Lens and Laser Care

At the core of your machine's ability to cut is a clean, unobstructed path for the laser beam. Contamination here is incredibly costly.

The Silent Killer: Dust, oil mist, and spatter on the protective and focusing lenses act like sunglasses, absorbing intense laser energy. This leads to poor cut quality, unpredictable power delivery, and ultimately, burnt lenses or even catastrophic damage to the laser source itself.

The Proactive Protocol: Implementing a disciplined, regular cleaning routine with the right tools (cleanroom wipes, appropriate solvents) is step one. More critically, it's about source control—keeping the cutting bed clean and considering fume extraction at the point of generation. Choosing equipment designed for maintainability, like DP Laser's systems with quick-release lens assemblies and protective gas seals, transforms a delicate task into a quick, foolproof process.

The Long-Term Payoff: A pristine optical system ensures that every watt of power from your fiber laser reaches the sheet metal. This translates to consistent edge quality, maintained cutting speed over thousands of hours, and the avoidance of its most expensive component failures.

Keeping the Motion System in Motion: Guideways and Drives

The blazing speed and hairline accuracy of your cutter depend entirely on the health of its mechanical components.

The Grinding Truth: In a metal shop, fine abrasive dust is everywhere. When it mixes with old grease on linear guideways and rack-and-pinion drives, it creates a grinding paste that accelerates wear. You'll hear it as unusual noise and see it as lost precision in corners or positional drift.

The Hands-On Ritual: This goes beyond wiping. It requires periodically removing old, contaminated lubricant and applying fresh, manufacturer-specified grease. Checking belt tension and ball screw alignment is also crucial. Machines built with superior sealing and centralized lubrication points, a hallmark of robust engineering, make this vital upkeep far simpler and less frequent.

The Long-Term Payoff: A smoothly running motion system preserves the machine's innate accuracy and dynamic response. This means your cutter can handle complex, high-tolerance jobs not just today, but five years from now, safeguarding your investment's performance and resale value.

The Vital Systems: Cooling and Exhaust

Your laser's chiller and dust collector are its life support, managing heat and removing byproducts.

The Hidden Hazards: Ignoring the cooling system allows algae and mineral scale to build up inside the laser and cutting head, reducing cooling efficiency. This causes thermal throttling, power loss, and premature aging. A clogged filter in the exhaust system increases back-pressure, forcing smoke and particles to recirculate, which coats everything—including your precious optics—in a damaging film.

The Scheduled Service: Adhere strictly to coolant replacement intervals and use recommended fluids. Monitor the differential pressure gauge on your dust collector and change filters before they are completely blocked. Modern systems from thoughtful suppliers often include automatic alerts for these parameters, shifting maintenance from a guessing game to a managed schedule.

The Long-Term Payoff: Stable temperature control is non-negotiable for laser diode longevity. A clean, cool operating environment prevents a domino effect of failures. This proactive care is far cheaper than replacing a laser source or rebuilding a smoke-filled electrical cabinet.

The Digital Check-Up: Software and Calibration

The hardware needs care, but its "nervous system" requires attention too.

The Drift Factor: Vibration and thermal cycling can cause microscopic shifts in the beam path over time. This leads to inconsistent focus position across the cutting bed, making your first part perfect and the last part scrap.

The Precision Routine: Periodically running the machine's built-in calibration cycles for beam alignment and focus nozzle height is essential. So is backing up your custom cutting parameters and material databases. Starting with a machine known for its precise factory calibration and stable software platform sets a higher baseline that's easier to maintain.

The Long-Term Payoff: Regular digital and optical calibration guarantees repeatability. It ensures that the perfect cut you programmed is the cut you get, every time, on any part of the table. This eliminates waste, reduces job setup time, and delivers unwavering quality to your clients.

Conclusion: The Smart Buyer Calculates Total Cost of Ownership

The true price of a laser cutter isn't its purchase order number. It's the Total Cost of Ownership (TCO): the sum of acquisition, energy, maintenance, downtime, and final depreciation. A straightforward, disciplined daily and weekly upkeep plan is the single most powerful lever to control this TCO. It can effectively halve your annual equipment cost by doubling its productive lifespan. This isn't just about saving on repairs; it's about ensuring predictable capacity, winning more bids with reliable delivery, and building a reputation for quality. DP Laser constructs equipment with serviceability and durability in mind, empowering users to become masters of maintenance. Because the most profitable machine in your shop isn't necessarily the newest—it's the one cared for the best.