The role of cooling technology in high-power laser cutting.

The "Invisible Guardian" in High-Power Laser Cutting: How Advanced Cooling Technology Enables Superior Processing

In the realm of industrial laser cutting, the spotlight often shines on impressive kilowatt-level beam power, focusing on breakthroughs in cutting speed and thickness. However, the true unsung hero driving consistent, stable equipment operation and ensuring long-term, exceptional performance is a sophisticated and robust thermal management system. Especially for modern manufacturing that pursues extreme productivity, advanced cooling technology has quietly become the "invisible champion" determining equipment reliability and processing quality.

Heat: The Ultimate Challenge Behind High Performance

Any high-power laser equipment generates immense waste heat during operation. If this heat cannot be dissipated promptly, evenly, and stably, it will directly lead to degraded beam quality, drastically shortened core component lifespan, and even irreversible hardware damage. Issues like focal point drift, rough cut surfaces, and power fluctuations—often, the root cause of many processing problems lies not with the laser itself, but with uncontrolled heat.

The Foundation of Stable Production: Why the Cooling System is Mission-Critical

On automated, continuous production lines, an unexpected shutdown or quality fluctuation can lead to significant losses. The reliability of the cooling system is directly linked to:

Processing Consistency: Maintaining optical components and the laser source at a constant temperature is essential for achieving consistent kerf width and smooth cut edges.

Equipment Durability: Effective cooling significantly extends the service life of core components like the laser generator, cutting head, and lenses, lowering the total cost of ownership.

Production Continuity: Especially for smart factories operating 24/7 uninterrupted, the cooling system is a key piece of infrastructure ensuring smooth production flow.

Technological Innovation: How DP Laser Empowers Equipment with Cooling Technology

As a solution provider deeply rooted in the laser industry, Shenzhen Dapeng Laser Equipment Co., Ltd. (DP Laser) has a profound understanding of the decisive impact thermal management has on equipment performance. We integrate advanced cooling principles deeply into our product design, ensuring every machine is built with the "robust constitution" needed for high-load processing.

1. Precision Temperature Control with Separate Circuits

Our high-end fiber laser cutting machine and laser welding machine series feature dual-circuit independent cooling for the laser source and the cutting/welding head. This ensures precise control over the distinct temperature requirements of different zones, preventing thermal interference at the source. It allows our equipment to maintain exceptional beam quality and processing accuracy even during prolonged, high-intensity operation.

2. Active Protection for Critical Components

Within our core laser cutting heads and handheld laser welders, we prioritize the real-time temperature of optical elements. Through optimized coolant channel design and the use of high-quality materials, we ensure critical lenses receive sufficient cooling, effectively suppressing the thermal lens effect. This guarantees a stable processing focal point, delivering consistently superior performance whether tackling thick-plate cutting or precision welding.

3. Smart Connectivity for Predictive Maintenance

DP Laser's intelligent equipment supports advanced system connectivity. The operational status of the cooling unit—including key parameters like water temperature, flow rate, and pressure—can be monitored in real-time. This goes beyond the convenience of remote management; it forms the foundation for predictive maintenance. Potential issues can be flagged early, minimizing unplanned downtime and providing solid, reliable production assurance for our partners, particularly those in demanding fields like new energy vehicles, aerospace, and heavy machinery

DP Laser: Delivering Smart Laser Solutions for All Scenarios

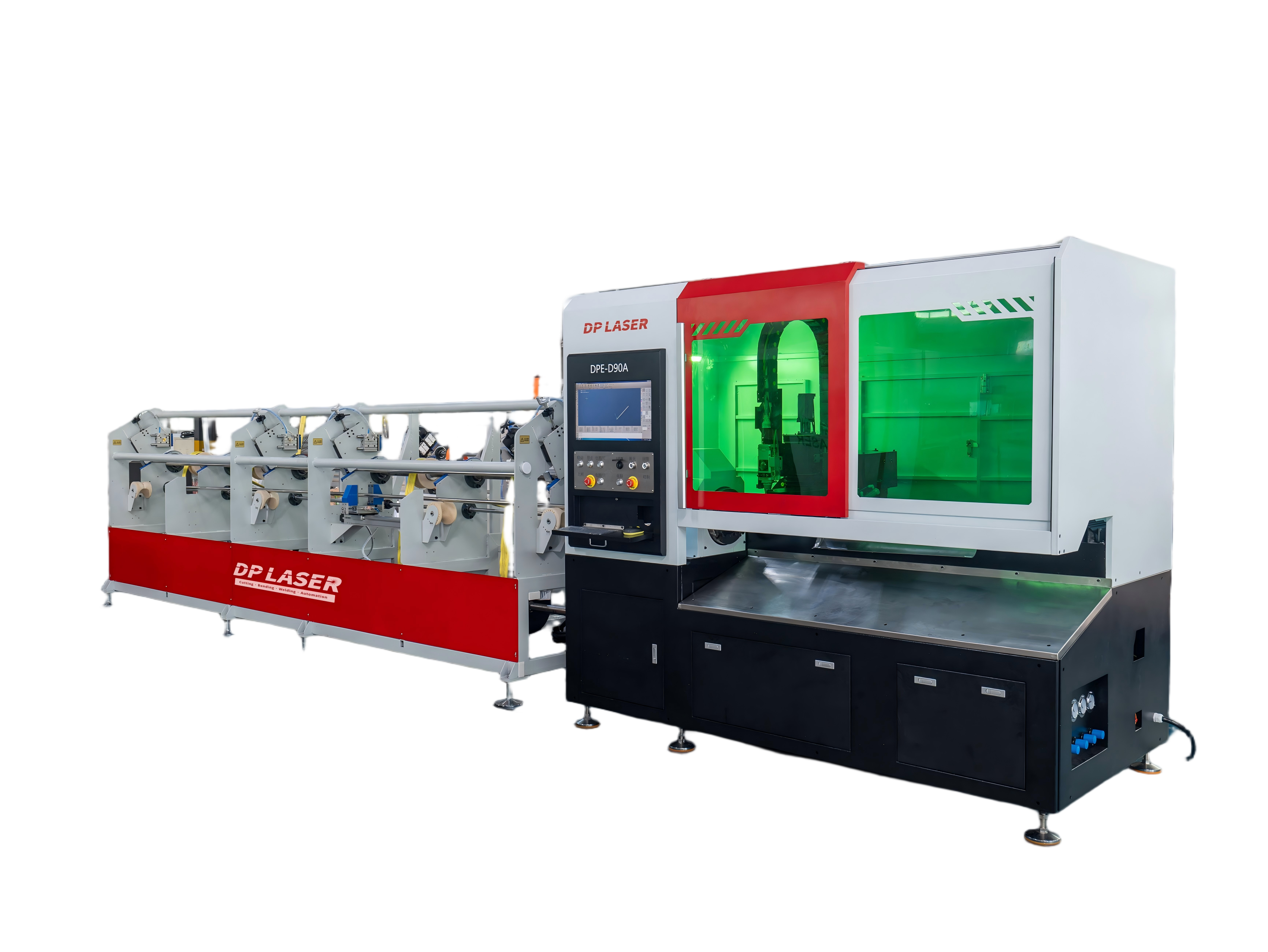

From precision tube laser cutting machines to efficient handheld laser welders, from standard laser cutting equipment to customized metal processing lines, DP Laser is committed to providing smart laser solutions for all scenarios to global industrial customers.

We understand that excellent equipment results from the perfect integration of superior core components and top-tier systems engineering. Therefore, we focus not only on laser power and mechanical precision but also on continuous investment and innovation in foundational technologies like the cooling system. This ensures that every one of our fiber laser cutting machines and every set of our laser welding systems delivers lasting, stable, and high efficiency on our customers' production floors. We strive to be the most trustworthy partner for our clients as they enhance their competitiveness and transition towards intelligent and flexible manufacturing.

Conclusion

Choosing laser equipment means choosing not just a beam of light, but a complete, reliable, and highly efficient system. Cooling technology is a vital component of that system. It silently safeguards the equipment's peak performance, ensuring every minute of production creates value.

Choosing DP Laser means choosing a commitment to long-term, stable production. With solid technology and dependable products, we empower you to harness the power of light and heat, achieving manufacturing excellence.