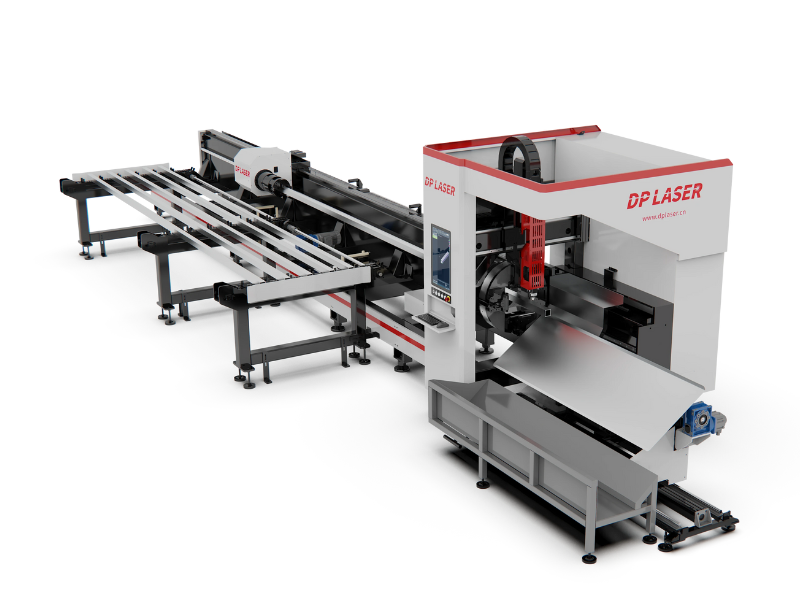

DPLASER’s G Series Fiber laser tube cutting machine

DPLASER’s G Series Fiber Laser Tube Cutting Machine

Featuring 100m/min cutting speed and ±0.02mm/m accuracy – empowers SMEs with a “speed + precision” competitive edge.

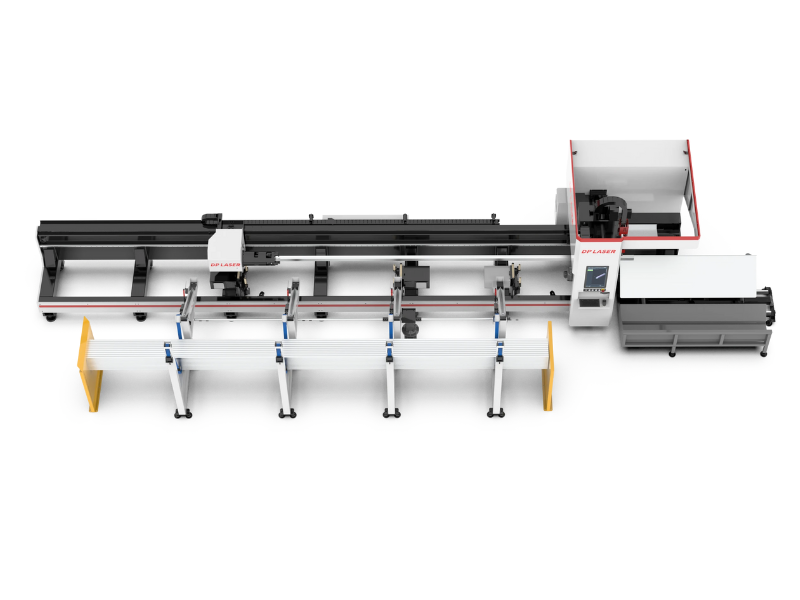

1. 100m/min Cutting Speed: 30% Daily Capacity Boost, Small-Batch Flexibility Made Easy

Traditional tube cutting equipment maxes out at ≤60m/min (XY-axis speed).

G6524CG redefines speed with:

-

Lightweight transmission structure

-

Bochu 3000DE-A system

-

100m/min XY-axis speed (Top 5% among same-class industrial laser machines)

Case: Φ50mm×2mm round tube cutting

-

Traditional: 28s per tube

-

G6524CG: 18s per tube

-

8-hour output:

-

Traditional ≈600pcs

-

G6524CG ≈1100pcs (53% capacity boost)

-

💡 Applications:

Automotive seat frames, bicycle/motorcycle frames, furniture legs (small-batch/high-mix), medical bed tubes (precision small orders), and other metal tube mass production scenarios.

2. ±0.02mm/m Positioning Accuracy: Secure Premium Orders, 20% Profit Margin Uplift

SMEs often lose premium orders due to “poor cutting accuracy (≥±0.05mm/m)”.

G6524CG eliminates this risk with:

-

High-precision ball screws

-

Servo motor closed-loop control

-

Positioning accuracy: ±0.02mm/m

-

Repeat positioning accuracy: ±0.02mm/m

Customer Case:

Wenzhou O**ng Sanitary Ware cuts 12mm thick-walled square tubes (for premium shower heads).

-

Traditional cutter: 0.2mm hole deviation → assembly jams

-

G6524CG: Deviation ≤0.02mm → directly serves international brands

-

Result: $0.43 profit increase per tube (¥3 RMB)

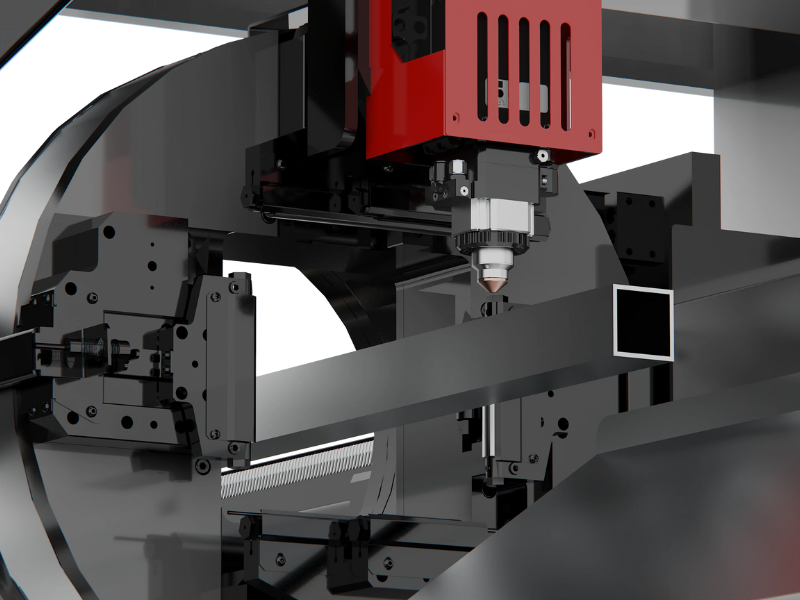

3. 1.5G Acceleration + Infinite Rotation Axis: Complex Tubes “One-Pass Cutting”, No Secondary Processing

For complex orders (bent tubes, irregular-shaped tubes), G6524CG delivers:

-

W1/W2 infinite rotation axis (360° continuous rotation)

-

1.5G maximum acceleration

Enables:

-

Guardrail bent tubes “one-pass cutting” (no segment clamping)

-

Free capacity bottleneck analysis of existing equipment

-

Custom “small-batch fast response” cutting solution (including time/cost calculation)